3D Scanning and CAD Conversion in Reverse Engineering

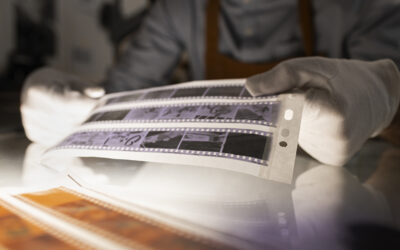

Reverse engineering is a process involving thorough examination of a product or an object to understand its various visible components and then planning the deconstruction process to enhance the object. 3D scanning is one of the most efficient ways to generate CAD models. It becomes useful especially if the physical object has a complex or irregular shape.

Reverse engineering makes use of the existing component and prevents the need for building a specific component. An object has many different sub-components that are interlinked with each other and when the object undergoes reverse engineering, it requires accurate measurement which cannot be measured individually. But with 3D scanning CAD models can be developed which helps in measuring high density, geometry, curvature and other difficult areas.

Benefits

- Minimizes the need for manual deconstruction

- Gives precise diagram and measurement

- Allows changes to design

- Removes the hardship of measuring inconsistently shaped or hard-to-measure components

- Makes the process of reverse engineering easier

The possibilities of 3D scanning are numerous. You can capture anything in the physical world and have a digital model of it made within minutes. Companies make us of 3D scanners and software either in-house or with outsourced document scanning services for various purposes such as:

- Make large volume customized products for various business sectors

- Verify product quality by comparing the manufactured parts to CAD designs

- Create CAD models of real parts and thereby update existing products, make new ones or capture lost designs

- Scan building to create accurate 3D models of those

Outsourcing to providers of CAD conversion services is a good option when it comes to ensuring affordability, accuracy and efficiency. Customized scanning and conversion solutions are available for architectural firms, engineering firms, and construction companies among others.